They deform in a precisely calculated manner in the event of a rear collision in order to absorb as much impact energy as possible. The rear periphery of the frame structure consists of aluminium components designed to form a so-called crash box. Because of the considerable heat given off by the engine and, in particular, the turbocharger, which operates with exhaust gas with a temperature of up to 1.000 ☌, this frame structure is made of rust -free, heat-resistant stainless steel. The steel frame mounted beneath it as a structural element accommodates the 16-cylinder engine. A carbon fibre crossbeam screwed onto the two longitudinal supports forms the rear edge of the frame structure. These longitudinal supports are also made of carbon fibre to make them torsionally rigid and lightweight.

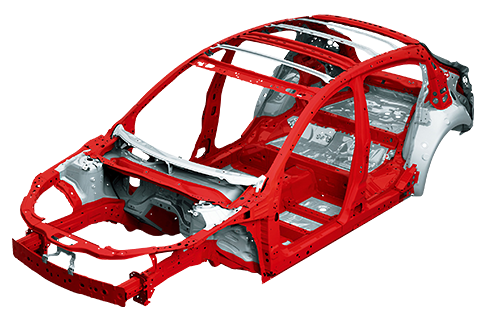

Mounted to the rear section of the monocoque are so-called “bags”, which serve as top longitudinal supports and which also accommodate the MacPherson struts of the rear axle. The tank area forms part of the monocoque. The rear section of the monocoque is designed with a hollow space to hold the 98-litre saddle fuel tank which surrounds the transmission and which is separated from the passenger area. The centre of the frame structure is formed by the carbon fibre passenger cell, which is built in exactly the same way as the survival cage of a Formula 1 racer as a monocoque construction weighing roughly 110 kilos. The Bugatti development team differentiates between four fundamental structural modules with defined, highly complex requirements profiles. New standards have been set in the disciplines of torsional rigidity, passenger protection and lightweight construction.

The development goals of the world’s most fascinating sports car have been achieved. This outstanding structural rigidity produces extraordinarily precise driving performance in bends and very good stability when braking and accelerating”. Wolfgang Schreiber on the advantages of this ~~ structure: “The torsional rigidity from axle to axle is around 60,000 newton metres per degree, a value which is twice as high as that which is customary in modern series-built sports cars. This central vehicle structure is perfected by a highly complex frame structure attached at the front and rear. It consists of extremely sturdy yet featherlight carbon fibre. The passenger cell of the Bugatti Veyron 16.4 is comparable to the cockpit of a racing car and is designed in a monocoque construction as a survival cell for two persons.

For this reason, the Bugatti development team has created the ideal combination of structural rigidity and lightweight construction for the fastest production car in the world. The highest possible level of safety for the driver and passenger in all driving situations is one of the prime objectives of the development of the exceptional Bugatti Veyron 16.4 sports car.

0 kommentar(er)

0 kommentar(er)